How Laser Cutting Improves Efficiency in Metal Fabrication

Delays and inconsistencies can throw an entire project off course. That’s why laser cutting has become the backbone of modern fabrication, replacing older methods like plasma cutting and

shearing. As Operations Manager Michael Amos explained, “It’s really the foundation of modern fabrication. It’s the first process straight from the mill and the most widely used today.”

This matters because the very first cut sets the tone for everything that follows. Precision and consistency at the start mean fewer corrections, smoother assembly and less risk of downstream issues.

From outdated to advanced

Plasma cutting and shearing once carried the industry, but as tolerances tightened and designs grew more complex, their limits became clear. Enterprise Welding invested in lasers not just to modernize, but to remove those limits.

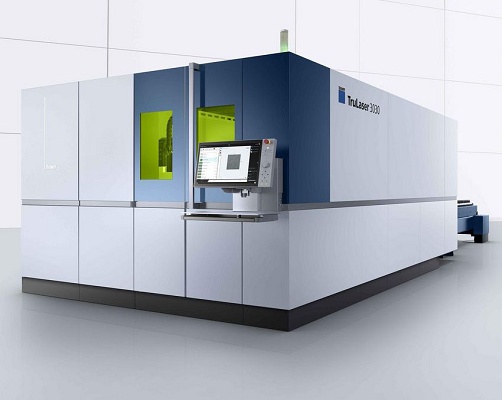

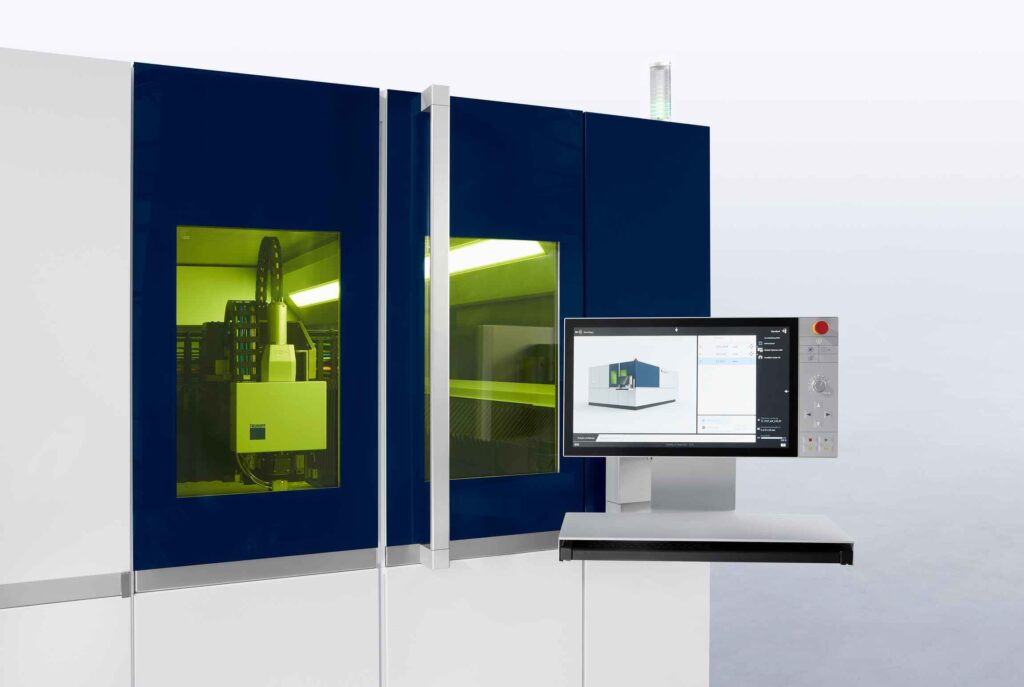

What does that leap in efficiency look like on the shop floor? Here’s a look at our TruLaser system cutting with speed and precision.

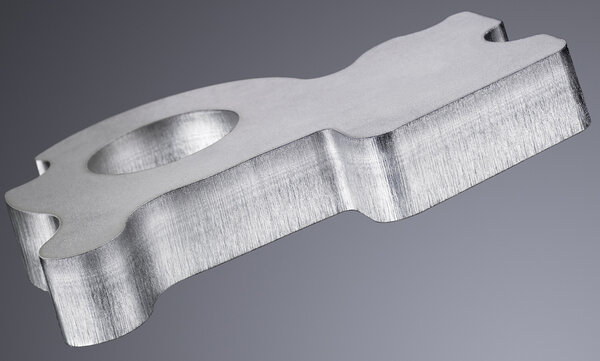

A cleaner, straighter, more accurate cut reduces rework and eliminates misalignment. Parts move directly into the next stage of production without delays, saving hours and sometimes days, compared to older processes.

This translates to higher-quality products in the field, longer life cycles and stronger brand confidence for our customers.

Flexibility across materials

Mild steel remains the staple of most fabrication work. But today’s fiber lasers handle stainless steel, aluminum, copper and brass, all the way up to one inch thick.

This versatility keeps production moving, even when specifications change. It allows new ideas, material shifts or design updates to move forward without outsourcing or extended downtime. That adaptability is what keeps complex projects on schedule and competitive in fast-moving industries.

This gives our customers the flexibility and support to test new ideas with different alloys, encouraging innovation.

Cleaner edges, faster turnaround

Fiber lasers cut three to four times faster than older systems, and the edges they leave behind are clean and ready to use. Secondary finishing steps like sanding or blasting are no longer needed.

Every unnecessary step removed from the process speeds things up and reduces the chance for error. Faster cutting and smoother edges shorten overall turnaround and keep production flowing steadily from one stage to the next.

This responsiveness helps us adapt to customer schedule changes, while overall speed and efficiency provide cost stability for end users.

Real-world results

The impact of laser cutting shows up most clearly on the shop floor. Work that once meant delays or outsourcing is now completed in-house with accuracy and speed.

- Aluminum: Once difficult to cut consistently, it’s now routine.

- Thick plate: Up to one inch cut in-house, eliminating delays tied to outsourcing.

- Repeat parts: Stored programs ensure repeat runs are identical year after year.

What were once obstacles are now standard, reliable processes, keeping production steady and predictable.

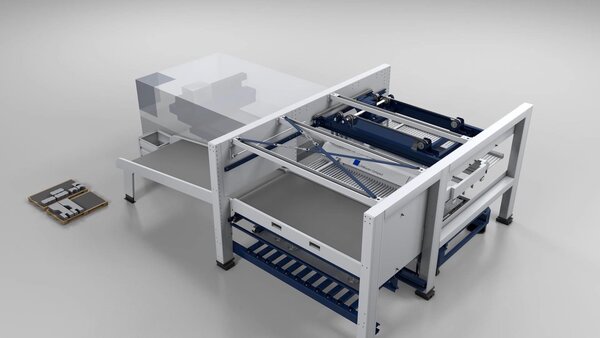

Efficiency beyond the machine

Automation and nesting software extend the benefits beyond the cut itself. Automated loading and unloading free operators to focus on higher-level work, while nesting programs maximize each sheet of material and minimize scrap.

Efficiency compounds at every level. Using more of each sheet lowers material costs, and removing repetitive tasks from operators’ hands keeps projects moving.

The outcome is shorter lead times, steadier schedules and consistent output.

Preparing for tomorrow

Enterprise Welding continues to look ahead with laser welding, additive machining and robotic integration on the horizon. Each of these technologies will streamline production by linking steps

and removing unnecessary handoffs.

By preparing now, the company is ready for the demands of tomorrow, ensuring future projects benefit from even greater efficiency, accuracy and reliability.

Conclusion

At Enterprise Welding, laser cutting isn’t just another tool; it’s the backbone of how work gets done. Precision, speed and versatility strengthen every stage of production, from the first cut to the final fit-up.

Every hour saved, every edge finished cleanly and every step made more reliable adds up to one thing: work that moves forward without delays, without surprises and with confidence it will be done right.