Cost-Effective Metal Fabrication: The Secret to Reducing Total Land Cost

When controlling manufacturing costs, success depends on managing Total Landed Cost (TLC), which deals with factoring in expenses tied to sources, design, production process, packaging and shipping costs, tariffs, and long-term performance. To avoid hidden costs, Enterprise Welding and Fabricating takes a proactive approach to not only minimize lead times, eliminate unnecessary freight costs and limit tariff exposure, our team also takes a collaborative approach in the upfront design process. It’s not about cutting corners but building products smarter from the beginning. During this upfront period, this is where our team has experienced the highest level of cost savings and avoidance.

Strategic material selection

Choosing the right material upfront can make or break the cost-efficiency of a project. The wrong spec can create challenges in sourcing, lead to longer wait times, drive up tariffs or increase machining and fabrication complexity. In contrast, standard-grade materials are typically easier to source, more affordable and offer better availability.

Non-standard materials can come with higher costs, whether it’s through added testing requirements, special certifications or import duties that can inflate pricing by massive dollar values. Enterprise Welding works with common domestic grades whenever possible to avoid these pitfalls. Not only does this help manage costs, but it ensures steady material flow, reduces risk and simplifies planning for our customers.

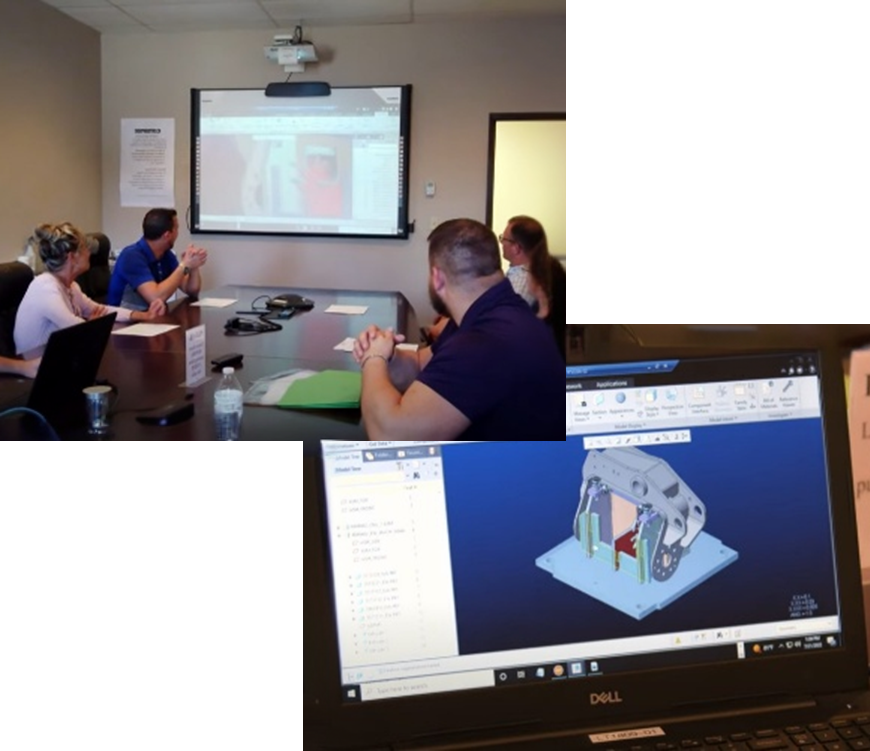

Design collaboration

One of the most overlooked cost drivers is design that does not reflect efficient process capabilities, and it’s often discovered too late after large investments in tooling and design are sunk into the project. That’s why Enterprise Welding engages with customers early in the design phase to eliminate unnecessary complexity, create efficiencies, reduce waste and rework, and any level of risk for warranty. We help refine parts through value engineering, so they do exactly what’s needed, without excess material, labor or cost.

Getting involved early allows us to avoid duplicate tooling, streamline manufacturability and shorten the timeline from concept to production. The result? Lower production costs, fewer redesigns, lower tooling and initial project investment cost, and overall, a more quality product with shorter lead times.

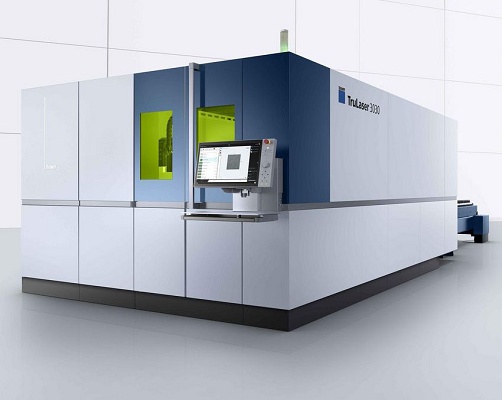

Precision fabrication

Welding and fabrication errors aren’t only production issues, but costly liabilities. Inconsistent welds, improper fits or poor-quality cuts can lead to reduced operational efficiency and, even worse, safety-related part issues.

Enterprise welding invests in high-quality robotics and automation, backed by certified welding processes and professionals to ensure the highest accuracy and repeatability. Every part undergoes inspections and routine in-process checks to ensure compliance with the customer’s needs. This helps to minimize rework, reduce scraps and maintain production schedules. Combining precision equipment with trained professionals allows for quality manufacturing to meet customer requirements from prototypes through full-scale production.

Lifecycle support

Enterprise Welding’s relationship doesn’t end when the product is shipped. We offer long-term support, product feedback analysis and opportunities for continuous improvement based on performance data and evolving client needs. Even if a product isn’t produced by our team from the start, we will get involved and offer continuous cost improvements over the life of that item. Our goal is to make products right the first time and every time; if another company has failed you in the past, we will support you the rest of the way. This allows us to build long-term reliability with our clients’ supply chain and production processes.

Packaging and shipping

Production at Enterprise Welding is operated out of the U.S., providing customers a significant advantage. This helps eliminate many of the costs and risk factors associated with overseas sourcing. Freight expenses are reduced by avoiding international container shipping, transit times are faster, enabling responsive supply chain operations, tariffs are avoided, logistics are improved, overall cash invested in this entire flow is avoided, and overall, world-class equipment and processes are utilized.

Enterprise Welding collaborates with OEMs to ensure that each part is packaged and labeled in compliance with customer specifications. This ensures that we can facilitate a more seamless integration into our customers’ assembly lines. It also helps us to manage our packaging in-house to reduce customer costs and prevent any damage that could disrupt production workflows.

Conclusion

Reducing TLC is about making smarter decisions at every stage of the fabrication process. From choosing the right materials and optimizing design to ensuring precision manufacturing and long-term durability, cost-effective metal fabrication is a strategic investment that pays dividends beyond the initial build.

Focusing on long-term performance versus short-term savings allows us to minimize maintenance, avoid costly downtime and extend the life of our equipment and infrastructure. The key to lowering your TLC lies in building it right from the start.

Contact us today to discuss your next project!