Innovation in Metal Fabrication

Innovation isn’t about chasing trends; it’s about solving real problems with better tools, smarter processes and a commitment to getting the job done right. In an industry where precision, reliability and turnaround times matter more than ever, staying ahead means constantly seeking ways to make improvements. That’s why Enterprise Welding and Fabricating has made innovation a core part of its operations.

Value of innovation in fabrication

Manufacturing today is quickly evolving. Tolerances are tighter, lead times are shorter and customer expectations are even higher. Innovation enables us to face all of this, ensuring we consistently hit the mark.

- Precision and consistency – As tolerances tighten, our ability to innovate ensures we’re consistently hitting the mark. Our focus on innovation allows us to deliver high accuracy and repeatability every time.

- Efficiency at every level – With tools such as RF+ and our integrated PFM system, we’ve improved how we manage inventory and schedule jobs.

- Staying competitive – Innovation isn’t just about fancy equipment. We invest in workforce education to ensure our team has the skills they need to tackle whatever comes their way.

Solving problems

Enterprise Welding has always maintained a deep relationship with our customers. In order to not only understand the fit/form/and function of a part, but to get entrenched into what our customers are trying to achieve, and how it will solve their problem, or the end user’s problem, is one of our main objectives. Some of our best ideas have come from something as simple as just purely listening to our customers. A recent project, for example, required a process switch to laser welding to meet speed and quality expectations. Investment in time and equipment in order to achieve everyone’s goals was required to get the job done right.

Our team just recently took accountability for quality issues, and in order to avoid long-term risks and possible warranty concerns, our team adapted and invested in a new quality system to provide long-term prevention.

This is how Enterprise Welding continues to build long-term trust.

Build on experience

Enterprise Welding and Fabricating was founded by two immigrants from Croatia, who brought a strong work ethic and a willingness to learn. With a farming background and a high school education, they built a company on long hours, grit and the belief that embracing new technology, no matter how unfamiliar, was the key to moving forward. They became the second-largest buyer of lasers in the country, even before they knew how to use a computer. That kind of forward-thinking still drives the company today.

As Enterprise Welding approaches its 50th anniversary this November, that founding legacy remains central. The drive to work hard, stay curious and support one another continues to shape every weld, every hire and every innovation. It’s not just about fabricating metal, but about building something that lasts.

Investing where it counts

At Enterprise Welding, innovation shows up where it counts, on the shop floor, in our machines and in the quality of the results we deliver.

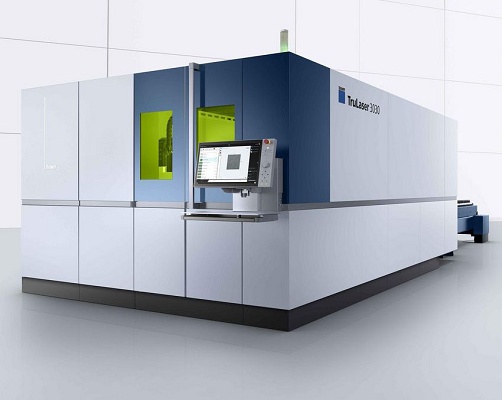

- Laser cutters and press brakes – we’ve upgraded to automatic laser cutters and press brakes that enhance accuracy, consistency and speed across production runs.

- Robotic welding – robotic systems ensure consistent welds on high-volume jobs where precision is key. The result is repeatable quality, faster turnaround and fewer reworks.

- New equipment upgrades – we’ve recently added new fiber lasers, a robotic press brake and advanced laser welders. Each piece contributes to better efficiency, higher-quality results and faster cycle times, as well as the ability to control costs for our customers.

- Next-generation ready – As technology reshapes our industry, we’re ensuring our team has access to the training, tools and support to keep up.

Domestic and global trends

More companies are reshoring production, opting for U.S.-based partners that can offer speed, reliability and tighter control. It’s no longer just about cost overseas, but about the confidence here at home, which is where we come in.

Sustainability is also gaining ground. Energy-efficient equipment, more innovative material use and waste reduction are no longer a nice addition, but part of doing smarter business.

As technology becomes the standard on the shop floor, the next wave of fabricators expects automation, robotics and digital tools to be part of their job. We are investing now and always will continue to here at Enterprise Welding so that we can stay ahead of innovation and ensure our team has what they need to deliver top-tier work every time.

Why it matters

Innovation means delivering better value to our customers.

- Cost efficiency – Leaner processes mean competitive pricing without sacrificing quality.

- Quality assurance – Innovation helps us catch potential issues early, reduce errors and uphold the highest standards on every job.

- Speed and flexibility – From intelligent scheduling to automated systems, we keep complex projects moving and adapt quickly when timelines shift.

- Reliability and trust – By building innovation into every phase of production, we become a partner our customers can continuously count on.

Conclusion

At Enterprise Welding, innovation isn’t a trend, but how we work. From tighter tolerances to faster lead times, we continually strive to improve how we deliver. With the right tools, a skilled team and a mindset focused on problem-solving, we aim to help our customers stay ahead.